DO NOT SCRAP IT! MODERATED NATIONAL EXCHANGE NEWSGROUP FOR SALVAGERS > Minnesota

> Ceramic finishing tumbling vibratory media precast

Ceramic finishing tumbling vibratory media precast

Ceramic finishing tumbling vibratory media precast

A very unique line of pre-cast ceramic media, quite different to the extruded ceramic media. It provides a dense distribution of abrasive particles designed to perform under the most exacting processes. This media contains a blend of abrasive which are not normally associated with other ceramic media's, each formulation has been developed to provide a finish that covers the wide spectrum of mass finishing in every conceivable type of machine. From light deburring and edge break to low micro inch finishes as well as the most aggressive requirements. Each shape is designed to provide the maximum surface contact while reducing lodgement to a minimum. With the introduction of new process techniques such as chemical accelerators to high energy finishing equipment a formulation is available that out performs other media. Where aluminum oxide impregnation is a problem the silicate filled media will overcome this or a combination of silicate and aluminum oxide that fills the void to reduce process cost and improve overall performance.

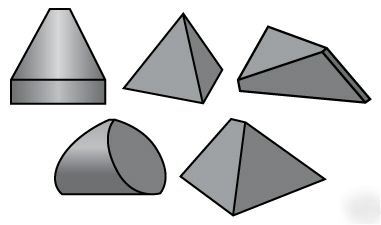

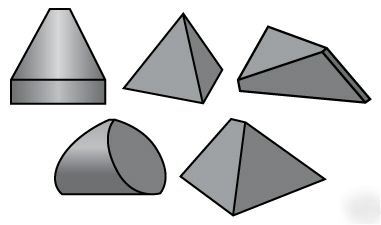

A very popular shape that provides excellent surface coverage. This configuration will provide more surface contact per cubic foot than any other shape of media. Ideal for all finishing equipment especially high energy disc machines.

This shape will search into difficult to reach areas, ideal for deburring slots and recesses. If comparing this shape to a triangle, it will generally perform faster, hold its shape constant while wearing, and provide a longer life cycle.

A shape that provides a long surface area, the multi facet design will enhance performance for surface blending and finishing. It has more edges than a triangle with up to half the weight when comparing similar compositions.

Designed to offer the best cutting and roll action, the large surface areas provide faster finishing and a reduction in lodgement. This shape can provide good deburring or burnishing finishes.

The five broad faces provide significant surface contact. The 34° angle on the four faces to offer sharper corners and long edges for penetrating difficult to reach right angles. This size will produce extremely fast cut down on all types of metals

For more media and finishing equipment visit our website at

Temporary Email: milton-poole@dontscrapit.com (Milton Poole)