DO NOT SCRAP IT! MODERATED NATIONAL EXCHANGE NEWSGROUP FOR SALVAGERS > New Mexico

> Solving casting problems cast mold foundry

Solving casting problems cast mold foundry

Solving casting problems cast mold foundry

bounce, yer money order will get lost in the mail and yer dog won't come home.

click on our "Contact Us" icon above for the quickest response to your questions.

SOLVING CASTING PROBLEMS CAST MOLD FOUNDRY

SOLVING CASTING PROBLEMS CAST MOLD FOUNDRY

SOLVING CASTING PROBLEMS CAST MOLD FOUNDRY

SOLVING CASTING PROBLEMS CAST MOLD FOUNDRY

SOLVING CASTING PROBLEMS CAST MOLD FOUNDRY

SOLVING CASTING PROBLEMS CAST MOLD FOUNDRY

SOLVING CASTING PROBLEMS CAST MOLD FOUNDRY

SOLVING CASTING PROBLEMS CAST MOLD FOUNDRY

SOLVING CASTING PROBLEMS CAST MOLD FOUNDRY

SOLVING CASTING PROBLEMS CAST MOLD FOUNDRY

SOLVING CASTING PROBLEMS CAST MOLD FOUNDRY

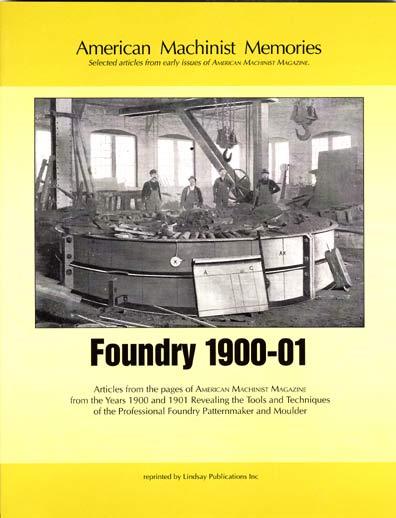

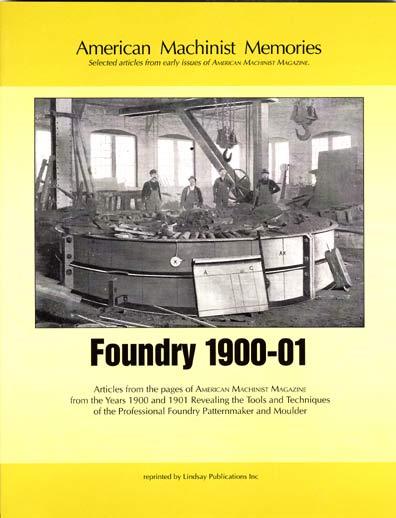

When I first saw this book I thought 'Ole Tom was on another one of his nostalgia bends. God knows why he does this from time to time. Must be trying to find his roots. But then I started reading this thing and found out that 'Ole Tom's a lot smarter than I thought! Here's a great collection of useful information in story form of how foundrymen back in 1900 solved some very interesting casting problems.

It's fun to read, very instructive and worthwhile for anyone to learn from who aspires to make castings. Metal still shrinks, takes up inclusions, gets hot cracks and feeds the same way today that it did in 1900 so the principles hold.

Yes, watching metal melt is fun enough. But the real excitement comes in making strange depressions in damp sand, and then seeing what appears after the metal has cooled and frozen. No matter how many castings you pour, molding and pouring never loses its appeal. I've been making castings for almost 50 years and I still get a thrill whenever I see the first casting off a new patern.

You get helpful material on brass founding, molding a gas engine bed, casting copper in sand, casting thin sections, and more.

You also are invited to watch projects larger than you and I will ever undertake, like molding an 18,000 pound flywheel in sand on the foundry floor. But it's fun to watch and imagine that you are part of the crew. What the old timers could do with little more than sand and lots of imagination is truly amazing.

Check out the contents. Take a look at some of the illustrations reproduced here. This is no textbook. These are letters from the men who did it, and here you'll find some arguments among the men who did it.

Molding a Flywheel. * The Swelling of Cores * Molding a Propeller Wheel in Green Sand. * Using Loose Pieces Instead of a Core. * Making Follow Boards. * Very Different Ways of Making a Simple Pattern. * Molding Locomotive Driving Wheels. * Brass Founding - Gates and Gating. * Molding a Lathe Bed. * Casting a Double-Thread Worm. * The Draftsman, the Pattern Maker and the Molder. * A Couple of Foundry Devices. * How to Mold a Drum. * Making Half-Round Core Boxes. * A Bracket Casting and Pattern - A Detail of a Locomotive Grate. * Some Cheap Core Boxes. * Brass Founding - The Use of Scrap Metals in Alloying. * Yellow Brass Scrap * Mold Construction for Crayons and Lead Balls. * Rings and Ledges for Holding Babbitt in Cast Iron Boxes. * Babbitt Rings and Ledges. * Molding a Casting by Bedding in the Floor. * Molding a Gas Engine Bed in a Three-Part Flask. * Pattern Making Pipe Work. * "Coring Out.". * Fitting up a Brass Foundry. * Making Sand Castings of Copper. * Brass Scrap. * The Pattern Work and Molding for a Single Casting. * Enlarging a Core. * A Process for Hardening Copper. * Fastening the Arms of a Wheel Pattern. * A Special Casting from a Regular Pattern. * Casting a Tangye Engine Bed. * Improving the Molding of the Special Casting. * Molding the Special Casting. * Pattern Making - Thin Rings. * Molding a Grinder Bed. * Making Thin Castings. * Artistic Bronze Casting - French Sand * Making Barrels for Cylinder Patterns. * A Pattern for a Cylinder Lining. * A Straight Casting from a Crooked Old Pattern. * Making Cylinder Pattern Barrels. * Machine Molding. * Making a Plunger Pattern. * Gear Molding Machine. * Molding a Crosshead Guide With a Pattern Which Makes its own Core. * Fitting Up a Brass Foundry. * Making a Small Casting With Green Sand Core. * Pattern Making that Makes Work for the Molder. * Casting a Housing for a Saw Mill. * A Combination Pattern. * Thin Brass Castings. * Molding Gap Lathe Beds. * Molding a Special Pipe. * Molding a Special Casting. * Sweeping a Mold for Paint Mill Pan. * How Carbons for Arc Lamps are Made. * Plate Molding for Small Work. * Molding Land Rollers.

Fun reading. Instructive. Valuable foundry problem reference to have. Study these tricks and tips from the old-timers not found in textbooks.

I have and have read just about every book offered by the American Foundrymen's Association and you won't find this kind of information in any of their books!

8-1/2" X 11" soft cover 72 pages very well illustrated with photos and drawings

Visit my MarketplaceAdvisor Gallery! Power Tools for Power Sellers!

Phone: (***) 744-4449 M-F 9:00 to 4:00 Pacific Standard Time

This item has been seen by alt people!

Temporary Email: Idagraham@dontscrapit.com (Ida Graham)