DO NOT SCRAP IT! MODERATED NATIONAL EXCHANGE NEWSGROUP FOR SALVAGERS > Alaska

> Construction

> Enhanced haas lathe vqc sl tl notching, fast threading

Enhanced haas lathe vqc sl tl notching, fast threading

Enhanced haas lathe vqc sl tl notching, fast threading

CUSTOM HAAS LATHE VISUAL QUICK CODE

REDUCE PROGRAMMING TIME INSTANTLY AND DRASTICALLY

Make your $519 VQC option actually make you money!

Hell with "Job Security" Run this software and get parts out the door

This code only works on lathe control versions 4.02 (May, 2000) to current (version 10.XX) Please check your machine before purchase!

Please inform me if you are interested in "Quick Code" templates so I can decide wether to offer an enhanced version.

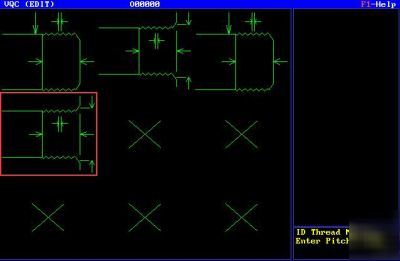

I've been creating custom HAAS "Visual Quick Code" templates for over a year. Due to the amount of labor and experience it takes to write redundant code for notching, cutoff, lead chamfers on bores, threading, and so on, I invested much time in learning how to fabricate HAAS Visual Quick Code. I create custom templates, graphics, and I support my work. I offer my "Enhanced HAAS Lathe VQC" in this sale. SL and TL series lathes are treated differently. The main difference is that the SL still homes the machine, and the TL rapids to "Z8." with an "M0." O.D and I.D. operations use 1 tool in the enhanced TL version. Many features of the VQC are hard-coded to eliminate operator keystrokes, redundancy and human error. I can tailor the templates to your specific needs before delivery, often without added fees. Let me hard code your most commonly used values for SFM, G97, MAX RPM, Feed, Tool #, Depth of cut, and so on. All templates include tuned-up standard VQC templates, but I've added the following important features:

Face grooving (trepanning) with user defined chamfers.

Leading edge chamfer option on all bores.

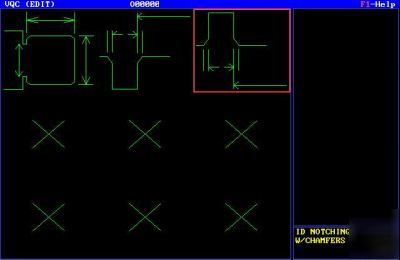

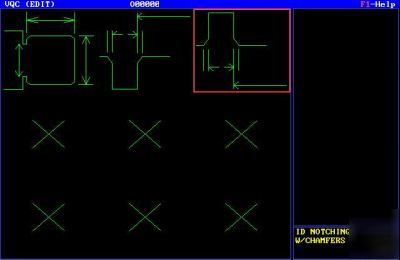

O.D. and I.D. notching with user defined chamfer.

Cutoff with user defined backside chamfer.

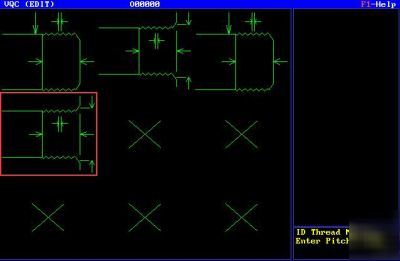

Macro powered threading that automatically generates code and adds a block delete dead pass.

All standard and metric threading needs is "OD", "Z Depth" and "Pitch". The operator then dials in the offset for a quick, quality thread. You have to have macro's enabled for this!

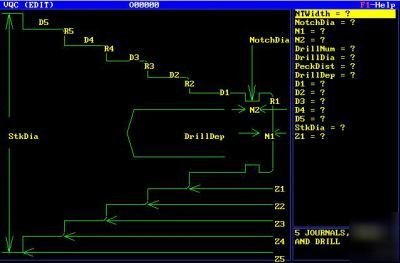

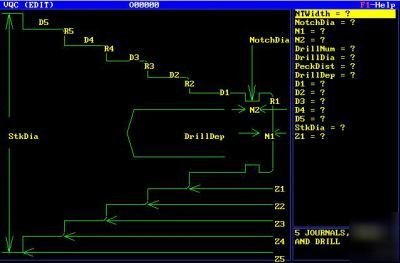

On the SL20, I added a 5 journal O.D template with user defined outside corner radii, HSS drill in 304 SS, and c-clip notch (on the minor dia) for common components at my workplace. I'm not going to delete it, as this is a somewhat common bearing shaft template. The drill speed is automatically calculated based on diameter for all-day operation without burning up the drill.

I can generate custom templates and packages for anyone's needs. I haven't had a need to generate mill templates, but I can provide experienced service for milling as well.

I stopped wasting my time, stop wasting yours. Thanks for looking, if you have questions, don't hesitate to ask.

Temporary Email: S-Callahan@dontscrapit.com (Sarah Callahan)